Sercel is pleased to announce the launch of the world’s first Vibrator Auto-Guidance solution, designed to increase vibroseis productivity by up to 10%. The solution can be fitted to all Sercel Nomad seismic vibrator trucks and works by optimizing a truck’s travel time to the next vibrating point (VP) and reducing baseplate dead time. This provides an increase in source efficiency and consequently a cost saving for acquisition.

Deployed on seismic survey projects around the world, Sercel Nomad vibrators are renowned for delivering high-performance broadband vibroseis in the harshest environments. Boasting the latest innovations in shaker and hydraulic circuitry design, they are recognized for their environmental credentials based on low-emission engines and an IPM (Intelligent Power Management) system, which optimizes engine efficiency to reduce fuel consumption by up to 15%.

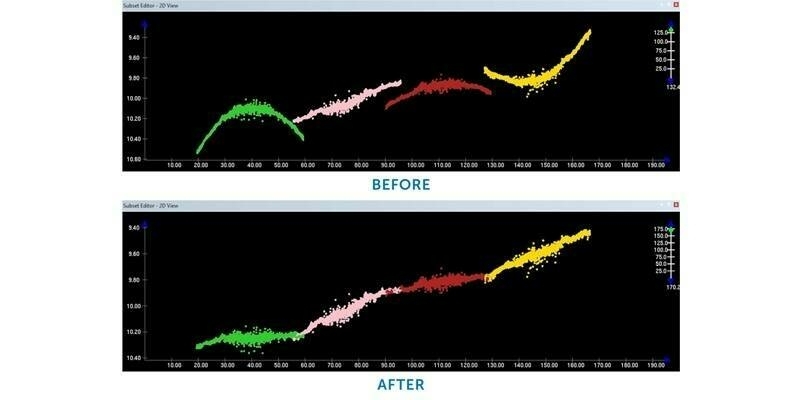

The addition of Vibrator Auto-Guidance optimizes vibroseis productivity in two ways. During operations, the truck’s deceleration is adjusted and controlled automatically. This reduces both its travel time between VPs and any operator-induced delays. Additional time is saved by reducing dead time spent on deploying and recovering the baseplate. The descent of the baseplate is anticipated by the system and commences before the truck has come to a complete standstill.

By positioning the Nomad vibrator with the highest degree of accuracy (within 1 m of the surveyed position), the Vibrator Auto-Guidance also ensures that the data collected is of the highest possible quality.

Pascal Rouiller, CEO of Sercel, said: “The launch of our new Auto-Guidance system brings additional value to our Nomad vibrator truck users. As well as boosting productivity and data quality, there are related HSE benefits, such as reduced operator fatigue, improved comfort and ergonomics.”

Subscribe to our newsletter

Stay updated on the latest technology, innovation product arrivals and exciting offers to your inbox.

Newsletter