An enhanced product customisation programme has been announced by Juniper Systems Limited, for their line of ultra-rugged handheld computers and sub-meter GNSS receiver.

Whilst product customisation has been performed by the company for several years, the programme has recently been elevated to include more options and flexibility.

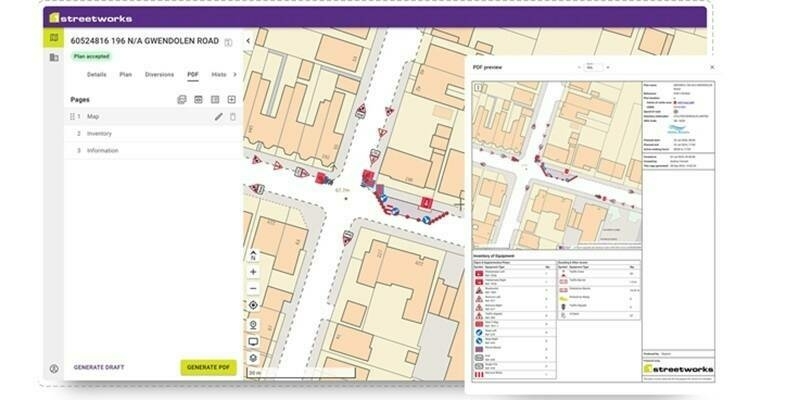

As an Original Equipment Manufacturer (OEM), Juniper Systems now offers four levels of product customisation, with options to fit the needs of most Value-Added Resellers (VARs), Independent Software Developers in need of hardware, or technology companies who desire equipment reflecting their brand.

‘Juniper Systems have customised our products for companies in industries such as radiation detection, surveying and mapping, construction and machine control’, said Mr. Simon Bowe, managing director at Juniper Systems Limited. ‘Now we’re expanding our services so even more companies can reap the benefits of having their personalised, branded rugged computers’.

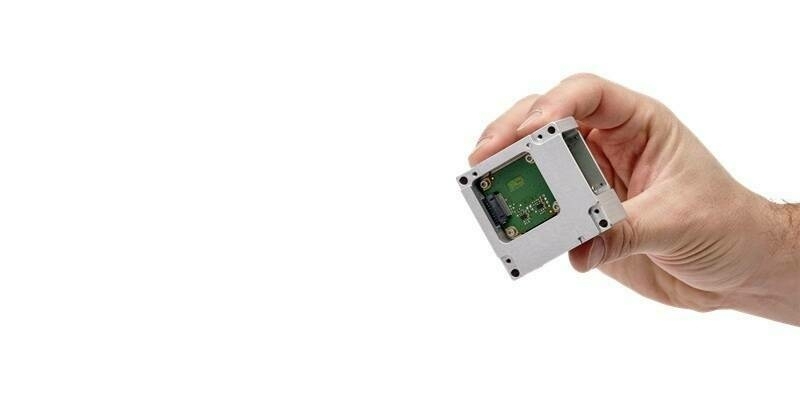

All of Juniper Systems’ ultra-rugged computers can be customised, including the flagship Mesa 3 Rugged Tablet, as well as the Allegro 3 and Archer 3Rugged Handheld Computers, and the Geode™ GNS2 Sub-meter GNSS Receiver.

The company released its plan for four levels of customisation, from basic appearance to the seamless integration of specific accessories:

• Level 1 provides primarily cosmetic enhancements, including custom logos, brand colors, shipping boxes and labels, with options for logo placement and contact information.

• Level 2 allows for proprietary functionality to be added, such as a barcode imager, RFID, radio, sensors, and Controller Area Network (CAN) integrations, to name a few.

• If internal integrations are not feasible they can be added externally with a Level 3 customisation, whilst retaining the computer’s ultra-rugged IP68 rating and ergonomic features.

• Level 4 involves operating system customisations, such as a logo or splash screen on boot, the addition of proprietary applications, and custom accessories.

Levels of customisation can be blended, ensuring each customer gets exactly what is needed for their particular business.

Whilst Juniper’s computers are manufactured in Logan, Utah, U.S.A., they are shipped from and serviced at their EMEA headquarters near Birmingham, U.K. The Service Centre handles repairs, offers live tech support, and its proximity to Europe, the Middle East, Africa, and India eliminates expensive shipping costs and long lead times that can be experienced with far-east manufacturers.

Juniper Systems’ customisations can be implemented for lower minimum quantities than other OEMs require; customers can afford to have their own branded device without committing to excessive volumes.

This is particularly advantageous for small-and mid-sized companies who desire a high-quality rugged product but cannot manage thousands of units on hand.

‘We make the customisation process very easy, working with each customer every step of the way’, said Mr. Andy Cray, technical manager for Juniper Systems Limited. ‘From there, the level of complexity is up to the customer. We can do easy things like custom-colored bumpers on the Mesa 3 Rugged Tablet, or more sophisticated services, like ensuring the proper BIS Certification for shipment to India. It’s all up to the customer’.

Subscribe to our newsletter

Stay updated on the latest technology, innovation product arrivals and exciting offers to your inbox.

Newsletter