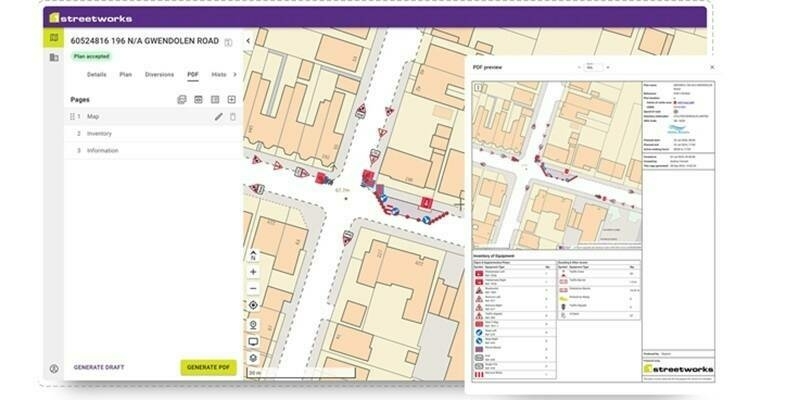

UG Pro monitors task-level activities, updating miner and machine workflows in real-time as the mine develops and produces ore. Developed specifically for mines lacking data networks underground, UG Pro optimises efficiency using tablets that store and forward critical information between supervisors and workers via network access points. Within the labyrinth of a commercial operation, digitalising all complex and simple mining tasks keeps data flowing. Visibility from mobile application dashboards ensures confidence in location and schedule adherence.

“As mines push deeper beneath the surface for deposits, the need for better communication and collaboration increases,” said Ola Rollén, Hexagon President and CEO. “Complexities that may be easier to overcome above ground require specific domain expertise and customised solutions below.”

UG Pro integrates with other Hexagon safety, fleet, and data visualisation solutions, as well as synchronises with data from third-party vendors. It leverages secure IoT protocol messaging brokers to expand information flow with minimal obstacles. UG Pro’s data architecture even allows customers to use their own business-intelligence analytics tools seamlessly with the platform. The solution provides a rich set of embedded intelligent tools for quickly modelling different economic and production scenarios with confidence.

True to Hexagon’s goal of narrowing the gap between what is and what should be, UG Pro brings mines one step closer to becoming autonomous connected ecosystems, linking all surface planning, scheduling, and dispatch with all underground mechanical, systems and human assets to optimise all tasks, physical locations and activities.

Subscribe to our newsletter

Stay updated on the latest technology, innovation product arrivals and exciting offers to your inbox.

Newsletter