Silicon double slit to be launched into space in 2025 with ESA’s FLEX mission

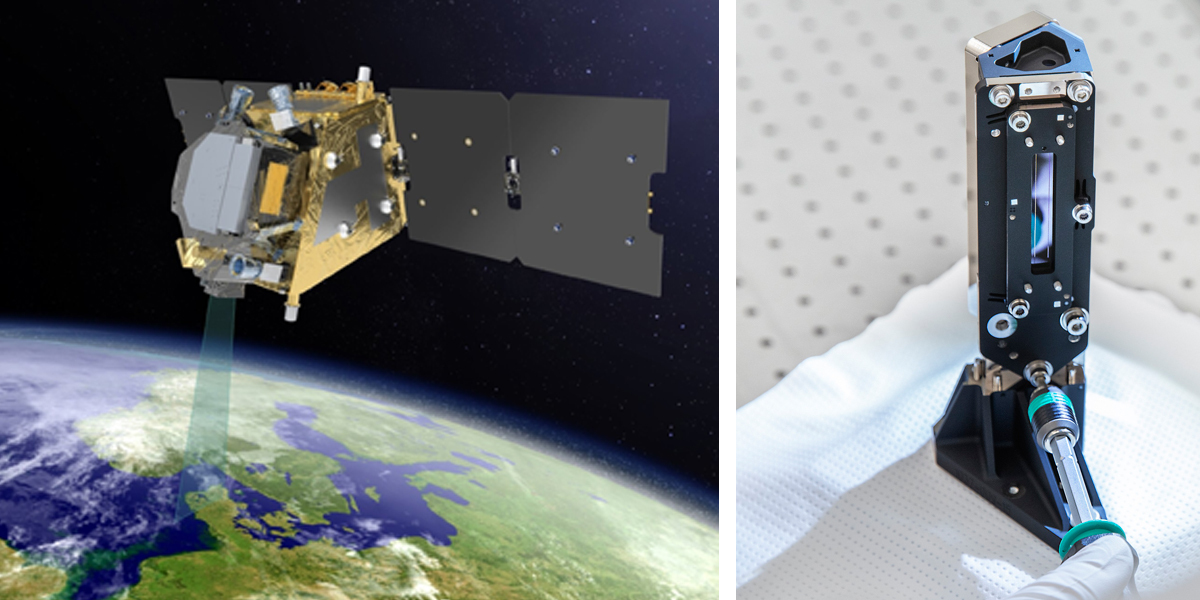

ESA plans to launch its FLEX mission in 2025. The aim is to collect data on the Earth's vegetation from space. For the spectrometer on board the satellite, researchers from the Fraunhofer Institute for Applied Optics and Precision Engineering IOF in Jena have developed and manufactured a double-slit assembly with exceptional accuracy as well as two high-precision mirrors. The development is currently being presented at SPIE Photonics West in San Francisco.

How much light do plants emit and what can this light emission tell us about the health of plants? The ESA mission "FLuorescence Explorer Mission" (FLEX) will address this question from 2025. At the heart of the satellite will be the "Fluorescence Imaging Spectrometer" (FLORIS for short).

Unlike many other spectrometers, however, FLORIS does not work with a single light channel, but with two. "This means that it needs two optical slits through which the light can enter the instrument," explains Falk Kemper. Kemper is a researcher at Fraunhofer IOF and heads the FLEX project at the institute. "To create these two channels, you need a high-precision arrangement of two slits, a so-called double slit. This is exactly what we developed and manufactured in Jena, together with high-precision mirrors for the spectrometer."

Components for space spectrometers with exceptional accuracy

The special feature of the double-slit assembly is its exceptional precision: each slit of the double-slit assembly must be manufactured with an exact width of 85 (+/-1) micrometres, and this over a length of 44.15 millimetres. "Slits that are too wide or too narrow would have guided too much or too little light onto the detector, making it impossible to evaluate the light component of interest for the mission," explains Kemper.

Special requirements also applied to the mirrors, which were manufactured in Jena and are intended to guide the light onto the detector inside the spectrometer: These had to have a roughness requirement of 0.3 nanometers rms (root mean square). "This roughly corresponds to the distance between one and two atoms," explains Kemper. "The requirements were incredibly high and were at the limits of what was technically feasible."

Special lithographic structuring for silicon-based double slit

The double slit was manufactured on a silicon basis. A special lithographic process chain was developed at Fraunhofer IOF for production, in which lithographic structuring techniques were adapted for etching silicon wafers: "Our strategy was to mask the silicon wafers, develop them and wet etch them in a time-controlled manner," says the project manager, explaining the process. "Due to the very high accuracies required, we had to go through numerous parameter iterations to get the production chain so stable that slits could be produced according to the requirements."

Finally, the slits were given a black coating in order to achieve the specified optical reflectivity and optical density. "The black coating of the slits also led to a change in the geometry of the slits and had to be retained accordingly when etching the slits."

Robust mounting for use in space spectrometers

The device is designed so that the silicon double slit is mounted in a mechanical holder. There, the two fragile slits had to be mounted highly parallel to the apertures in the holder, i.e., with an accuracy of less than 5 micrometers and a slit planarity of less than 10 micrometers. In addition, the two slits had to be installed in such a way that they would not deform or break - even when strong vibrations, temperature fluctuations and accelerations occur during the launch of the FLEX satellite.

In order to ensure the necessary robustness of the assembly, the researchers at Fraunhofer IOF therefore developed a special assembly concept, i.e. a strategy for joining different components together to form an assembly. "This was achieved using a combination of positive locking, clamping and bonding," reports Kemper.

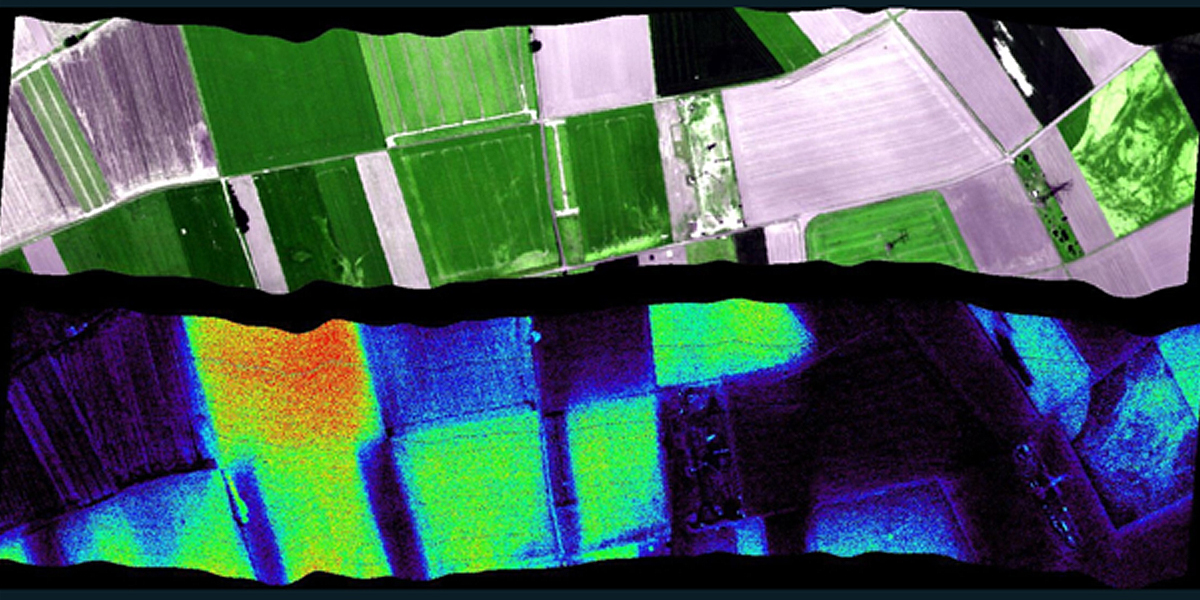

Double slit allows spectrometer to perform finer and broader light analysis

The special design of the FLORIS spectrometer with the double slit offers a decisive advantage for the objectives of the FLEX mission: "The double slit allows two channels to be operated in the spectrometer: one for high-resolution and one for low-resolution," summarizes Falk Kemper. The high-resolution channel can detect the smallest differences in the wavelengths of light, while the low-resolution channel can capture broader areas of the light spectrum. The combination of both channels enables a more comprehensive analysis of the light and therefore a detailed analysis of the plant vegetation.

FLEX mission to monitor vegetation data on earth

The FLuorescence Explorer mission, which is scheduled to be launched in 2025, will provide global maps of plant fluorescence, i.e., the emission of light by plants. This data is intended to provide information about photosynthetic activity as well as the health and stress of plants.

Such data are not only important for a better understanding of the global carbon cycle, but also for agriculture and future food security in the context of a growing world population. Until now, it has not been possible to measure the photosynthetic activity of plants from space.

The double slit was developed and manufactured at Fraunhofer IOF on behalf of OHB SE. Other partners involved in the realization of the FLORIS spectrometer are Leonardo S.p.A. and Thales Alenia Space. The joint client is the European Space Agency (ESA).

For more information about Fraunhofer IOF, please visit: http://www.iof.fraunhofer.de

Subscribe to our newsletter

Stay updated on the latest technology, innovation product arrivals and exciting offers to your inbox.

Newsletter